The packaging industry is undergoing a seismic shift. Driven by e-commerce booms, stringent regulatory demands, and an unwavering focus on speed and efficiency, automation is no longer a luxury but a necessity. Upgrading packaging equipment with robust and reliable gear motors is a critical investment. Choosing the right gear motor isn't just about getting a component – it’s about ensuring the smooth, consistent, and high-throughput operation of your entire packaging line. This article provides a comprehensive guide to gear motor brand selection and matching, considering key factors vital for successful automation upgrades. We'll also explore emerging trends in gear motor technology and how they contribute to a more resilient and adaptable packaging infrastructure.

Gear motors are the unsung heroes of modern packaging. They convert the rotational output of an electric motor into a lower speed and higher torque, enabling precise and powerful movement for various packaging processes. Think about it – from carton erecting and filling to sealing, labeling, and palletizing, gear motors are at the heart of these operations. Inefficient or poorly chosen gear motors can lead to:

Therefore, selecting the correct gear motor is paramount.

Before diving into specific brands, let's outline the crucial factors that should guide your decision-making process:

1. Torque Requirements: This is arguably the most important factor. Accurately calculate the torque needed for each application, considering load, speed, and acceleration requirements. Oversizing can lead to unnecessary cost and inefficiency, while undersizing guarantees failure.

2. Speed & RPM: Determine the required rotational speed (RPM) for the application. This will influence the gear ratio needed and the type of gear system.

3. Efficiency: Energy efficiency is a major concern, impacting operating costs and environmental footprint. Look for gear motors with high efficiency ratings. Modern gear motor designs, including those incorporating helical gears and optimized lubrication systems, offer significant efficiency gains.

4. Gear Type: Different gear types excel in different applications. Common types include: * Spur Gears: Simple, cost-effective but generally noisier. * Helical Gears: Quieter and more efficient than spur gears. * Planetary Gears: Compact, high torque density, and good efficiency. * Worm Gears: Offer high reduction ratios in a compact package.

5. Duty Cycle: Consider the operating conditions of the packaging line. Is it continuous, intermittent, or variable? Select a gear motor rated for the appropriate duty cycle.

6. Environmental Factors: Packaging environments can be harsh, with dust, moisture, and vibrations. Choose gear motors with appropriate IP ratings (Ingress Protection) for protection against these elements.

7. Size & Weight: Space constraints and overall equipment design necessitate considering the physical dimensions and weight of the gear motor.

8. Brand Reputation & Support: A reputable brand offers reliable products, robust warranties, and responsive technical support.

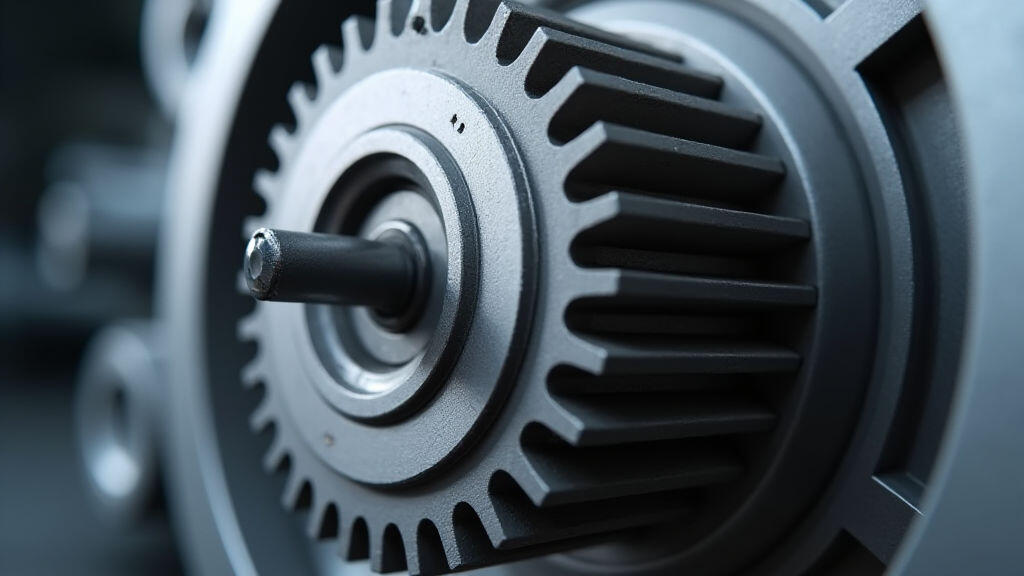

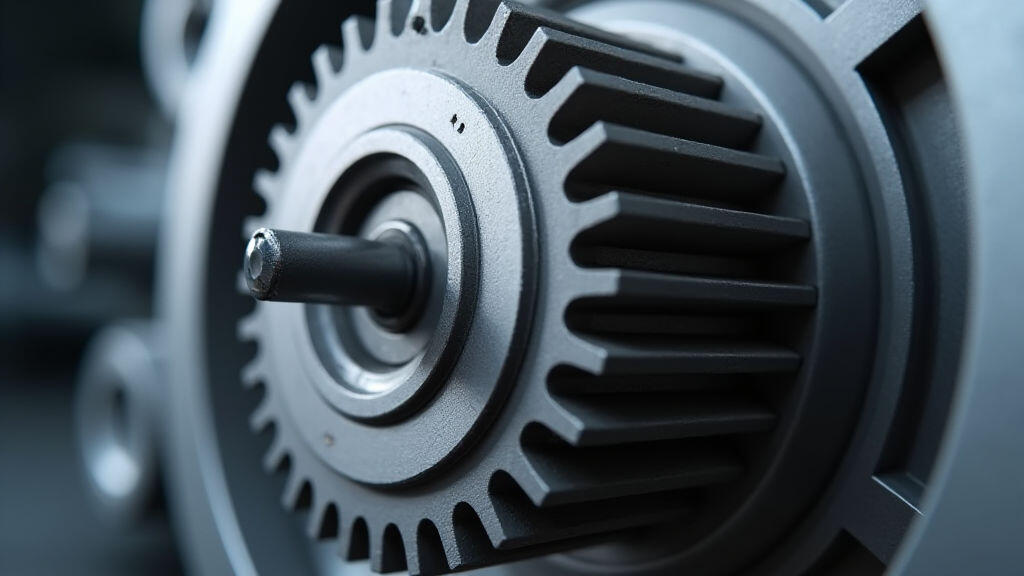

MES-Drive has established itself as a premier provider of high-performance gear motors specifically tailored for packaging automation. They offer a comprehensive range of gear motor solutions, encompassing various gear types, configurations, and power ratings. [Image: An AI-generated image showing a close-up of a high-precision gear motor from MES-Drive, with gears meshing smoothly. The image should convey a sense of quality and precision.  ]. MES-Drive distinguishes itself through:

]. MES-Drive distinguishes itself through:

Several trends are shaping the future of gear motor technology and impacting packaging automation:

1. IoT Integration & Predictive Maintenance: Smart gear motors equipped with IoT sensors can monitor performance parameters (vibration, temperature, current) in real-time. This data enables predictive maintenance, minimizing downtime and maximizing equipment lifespan.

2. Energy Harvesting: Some newer gear motor designs incorporate energy harvesting capabilities, converting mechanical energy back into electrical energy. This can contribute to energy savings and a reduced carbon footprint.

3. Additive Manufacturing (3D Printing): 3D printing is enabling the creation of complex gear designs and customized components, leading to improved performance and reduced lead times.

4. Increased Automation of Motor Selection: Software tools are emerging that assist engineers in selecting the optimal gear motor for a given application, based on detailed specifications and performance requirements.

To effectively match a gear motor to a packaging application, follow these steps:

[Image: An AI-generated image showing a comparison chart illustrating the different gear types (spur, helical, planetary, worm) and their respective advantages/disadvantages in terms of efficiency, noise, and cost.  ].

].

Upgrading packaging equipment with optimized gear motor solutions is vital for enhancing efficiency, reliability, and adaptability in today's demanding market. By carefully considering torque requirements, speed, efficiency, and environmental factors, and by partnering with reputable brands like MES-Drive, packaging companies can significantly improve their operational performance and maintain a competitive edge.

As the packaging industry continues to embrace automation and smart manufacturing, the role of sophisticated gear motor technology will only become more critical. The integration of IoT, predictive maintenance, and advanced gear designs promises to unlock even greater levels of efficiency, resilience, and sustainability in packaging processes. Investing in the right gear motors today is not just about powering equipment; it's about powering the future of packaging.

Leave A Reply

Your email address will not be published. Required fiels are marked